Infrastructure

Checkout all the Infrastructure

- Home

- Infrastructure

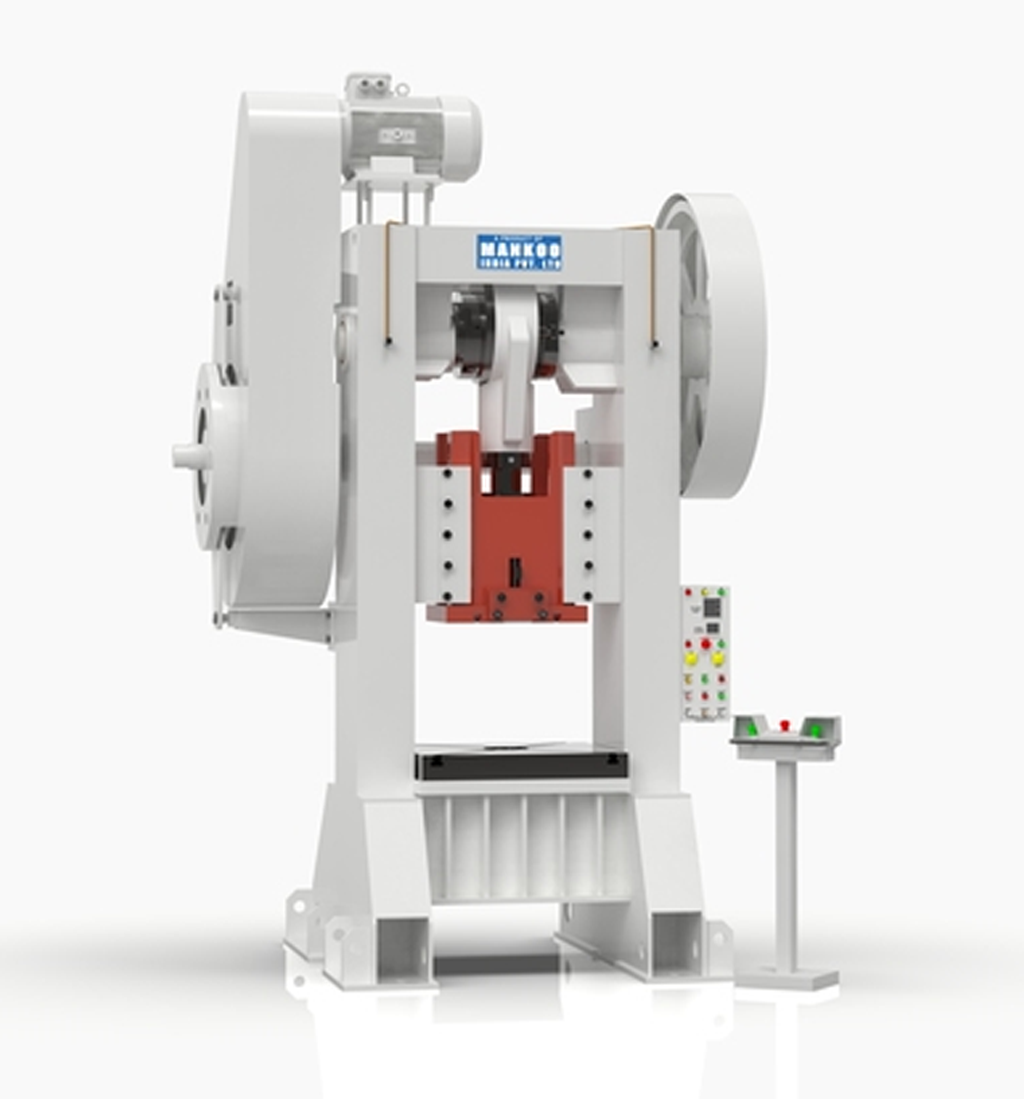

Press Shop

Press Shop

Ranging from 50 tons to 500 tons we have presses of all mechanical , hydraulic and pneumatic capabilities.DESIGN & R&D

DESIGN & R&D

- Specialized team of engineers , designers are dedicatedly working to serve our clients with high end quality products with optimal usage of resources

- This department itself is personally headed by our Directors Mr. Anil Luthra & Mr. Vikas Luthra being Engineer they just not only possess abundant technical know how of tooling but also inspires team to think creatively in aspects of design thinking.

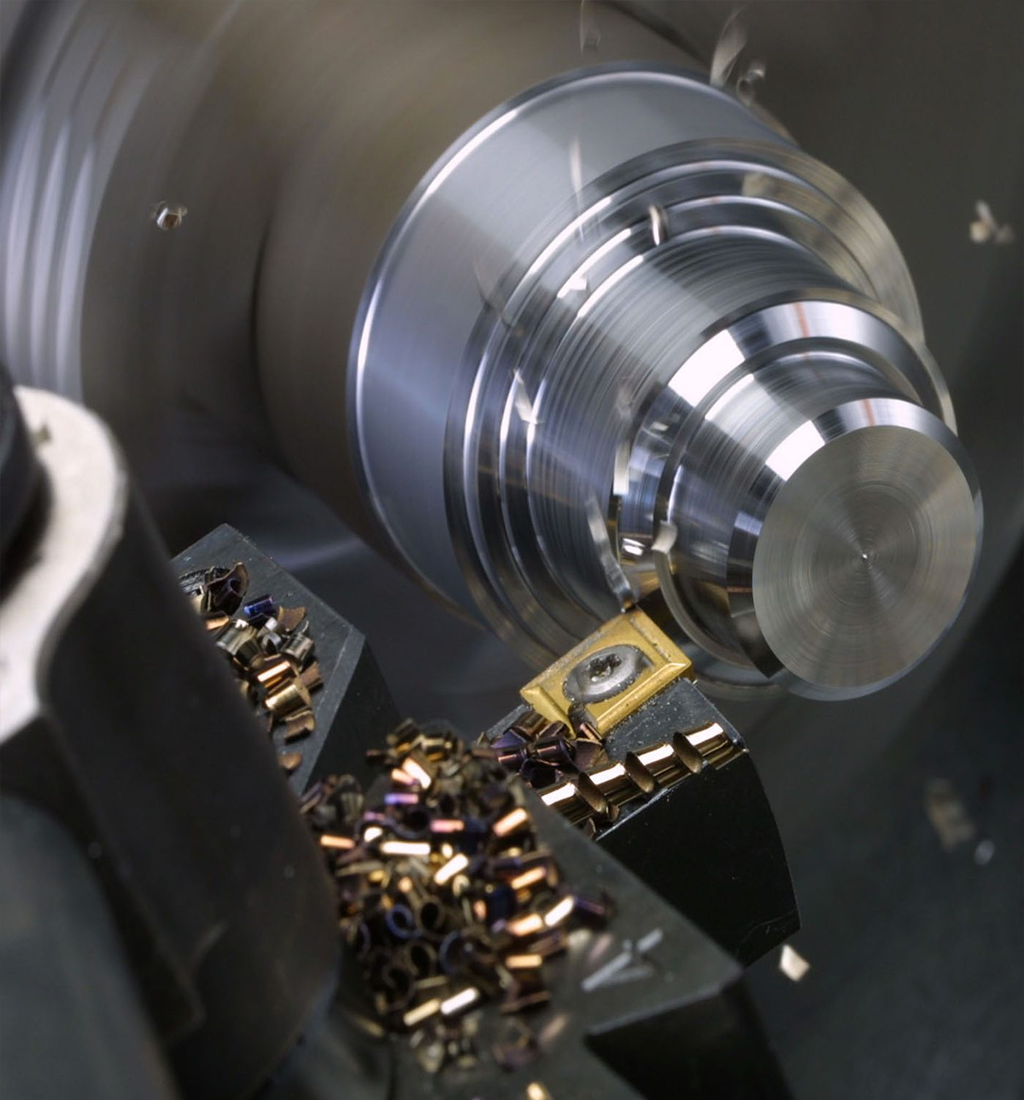

Machines

Special Purpose Machines

▶ To complete product manufacturing it needs an array of special purpose machines. As specific to Rim manufacturing line it does also needs SPM as- Ring coilers

- Butt welding machines- upto 400 KW capacity

- Roll forming machines

- Automated MiG welding machines

Packaging

Paint and Packaging

- As Paint is an essential part of manufacturing process which not only protect the component from atmospheric challenges but also looks of product.

- To handle it professionally we have automated phosphating coating line .

- Then product goes for top coat and then it gets baked in specialized ovens for its long life protection.

- All processes are always done sustainably in environmental conscious ways

Testing

& Inspection

Regular testing and inspection is the key to quality so special focus is always driven towards this aspect to deliver utmost quality with zero defect and to get aligned towards six sigma practices. Some Rigorous testing methods we comply are

Air Leak

Run Out testing

Weld shear